When people talk about diamond quality, they usually jump straight to carat size or price. But for those who spend a little more time learning, something else comes up again and again craftsmanship. This is where lazare diamond craftsmanship explained becomes important, because Lazare diamonds are not just mined and sold. They are carefully engineered, cut, and refined with a very specific philosophy that has been around for more than a century.

In simple terms, Lazare diamond craftsmanship refers to the precision cutting, optical performance, and consistency standards developed by Lazare Kaplan, a pioneer in modern diamond cutting. The goal has always been the same: extract the maximum brilliance from every stone, not just make it bigger.

This article breaks it down slowly, without rushing, so even if diamonds aren’t your daily topic, you’ll still get it.

What Is Lazare Diamond Craftsmanship?

Lazare diamond craftsmanship is a cutting and finishing approach developed by the Lazare Kaplan Diamond Company, a name closely tied to modern diamond innovation. Unlike mass-market diamonds, Lazare stones are cut to very tight tolerances, focusing on light return, symmetry, and balance.

What makes this approach stand out is consistency. Two diamonds with the same grading on paper can look very different in real life. Lazare craftsmanship tries to remove that uncertainty, which is something many first-time buyers only realize after comparing stones side by side.

For beginners who are still learning how cut quality affects appearance, this is closely related to the fundamentals explained in Aary Jewellery’s engagement ring buying guide for beginners, which walks through what truly matters beyond just the 4Cs

Core Principles Behind Lazare Craftsmanship

- Precision cutting using patented techniques

- Strict control of symmetry and proportions

- Emphasis on brilliance, not just size

- Limited production to maintain quality

This is not fast work. And it’s not cheap work either.

The History Behind Lazare Diamonds

Understanding lazare diamond craftsmanship explained properly means knowing where it started.

Lazare Kaplan was one of the first to apply mathematical principles to diamond cutting in the early 1900s. Before that, cutting was more about experience and guesswork. Kaplan believed light could be measured, controlled, and optimized.

A Short Timeline

| Year | Milestone |

|---|---|

| 1903 | Lazare Kaplan enters the diamond trade |

| 1919 | Develops early light-optimization cutting methods |

| 1950s | Supplies diamonds to luxury houses worldwide |

| Today | Lazare diamonds remain a benchmark for cut quality |

This long history is part of why Lazare diamonds are still referenced in professional gemology discussions.

How Lazare Diamonds Are Cut Differently

This is where things get interesting, and maybe a little technical, but not too much.

Precision Over Speed

Most diamonds are cut with efficiency in mind. Lazare diamonds are cut with patience. The cutter may sacrifice extra rough material to achieve ideal angles.

Focus on Optical Symmetry

Optical symmetry affects how light travels through the diamond. Lazare diamonds are cut so light reflects evenly across all facets.

Key cutting priorities include:

- Exact pavilion angles

- Balanced crown height

- Uniform facet alignment

This combination leads to a diamond that looks lively even under low lighting, which honestly matters more than showroom lights.

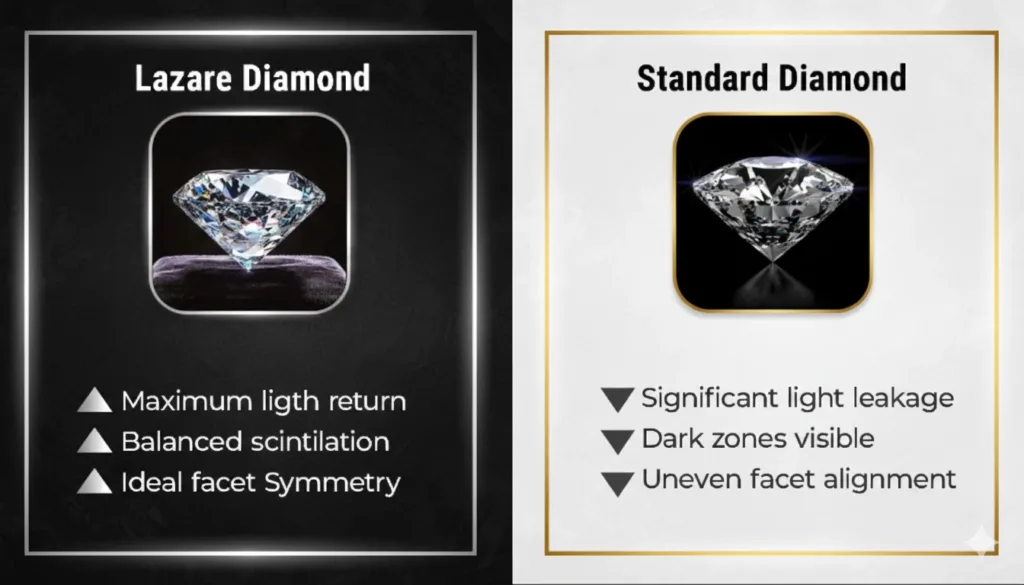

Lazare Diamonds vs Standard Ideal Cut Diamonds

On paper, many diamonds are labeled “Excellent” or “Ideal.” In real life, differences show up quickly.

| Feature | Lazare Diamond | Standard Ideal Cut |

|---|---|---|

| Cut precision | Extremely tight tolerances | Wider acceptable range |

| Light return | High and consistent | Can vary |

| Production volume | Limited | Mass-produced |

| Visual consistency | Very uniform | Stone-dependent |

This is why lazare diamond craftsmanship explained often comes up among buyers who already know the basics and want more control over quality.

Craftsmanship and Light Performance

Light performance is not marketing fluff. It’s physics.

When light enters a diamond:

- It bends (refraction)

- Reflects inside the stone

- Exits back to the eye

Poor angles leak light. Lazare craftsmanship reduces leakage.

Measured Performance Indicators

- Higher brilliance (white light return)

- Stronger fire (colored flashes)

- Even scintillation (sparkle pattern)

Gemological studies suggest cut quality can impact perceived brightness by up to 40%, even when carat weight stays the same. This is why a slightly smaller, better-cut diamond often looks better.

Certification and Quality Control

Lazare diamonds are usually graded by respected laboratories like GIA, but there’s an extra layer.

Internal Standards Beyond the Lab

Even if a diamond passes external grading, it may still be rejected internally if it doesn’t meet Lazare’s visual benchmarks.

This is important because lab reports measure parameters, not beauty.

Who Typically Chooses Lazare Diamonds?

From years of retail observation, Lazare diamonds often attract:

- Buyers comparing multiple diamonds side by side

- Clients upgrading from a first engagement ring

- People sensitive to sparkle and visual balance

- Those who value heritage and technical expertise

Many of these buyers don’t come with a fixed design in mind. They usually browse different styles first, comparing how a Lazare-cut diamond behaves in various ring settings. This is where exploring a curated jewellery collection helps narrow preferences before making a final decision.

Real-World Case Example: Visual Comparison

In controlled showroom comparisons, customers shown two diamonds of equal carat and grade often pick the Lazare stone first, even without knowing the brand. Once they learn why, the decision usually makes sense.

This kind of blind selection test is one reason Lazare diamonds maintain their reputation among professionals.

Common Myths About Lazare Diamond Craftsmanship

Myth 1: “It’s just branding”

Cutting tolerances and optical symmetry are measurable, not just branding terms.

Myth 2: “All ideal cuts look the same”

They really don’t, especially under natural lighting.

Myth 3: “Bigger is always better”

Light performance often matters more than size.

How to Evaluate Lazare Diamond Craftsmanship Yourself

If you ever view one in person, try this simple method:

- Compare under natural light near a window

- Tilt the diamond slowly

- Observe dark zones or uneven sparkle

- Compare with another diamond of similar specs

You’ll usually see the difference without being told.

Pro Tips Before Buying a Lazare Diamond

- Don’t rely only on the certificate

- Always view the diamond loose if possible

- Compare under different lighting conditions

- Ask about internal quality standards

These small steps help avoid regret later.

Conclusion: Why Lazare Diamond Craftsmanship Matters

Understanding lazare diamond craftsmanship explained is really about learning how much difference precision and patience can make. Diamonds may look similar at first glance, but craftsmanship separates the ordinary from the exceptional.

At Aary Jewellery, we work closely with expertly cut diamonds, including Lazare, and guide clients through real comparisons, not just certificates or sales talk. Our experience with high performance diamonds allows us to explain, show, and let you decide with confidence.

If you’re considering a Lazare diamond or want to see how craftsmanship changes everything, explore our collection and speak with our specialists directly at Aary Jewellery. Sometimes seeing it in person answers more than a thousand words ever could.

FAQs (Frequently Asked Questions)

Is lazare diamond craftsmanship explained mainly about cut quality?

Yes, but not only cut grade. It’s about how precise that cut is and how consistent the results are across stones.

Are Lazare diamonds worth the higher price?

For buyers who value sparkle, balance, and visual beauty, many feel the premium makes sense.

Do Lazare diamonds look better in everyday lighting?

Often yes, because they are optimized for varied light conditions, not just bright spotlights.

Can Lazare diamonds be certified by GIA?

Yes, most are GIA-certified, but Lazare adds its own internal standards.

Are Lazare diamonds suitable for engagement rings?

They are commonly chosen for engagement rings because of their brilliance and long-term appeal.